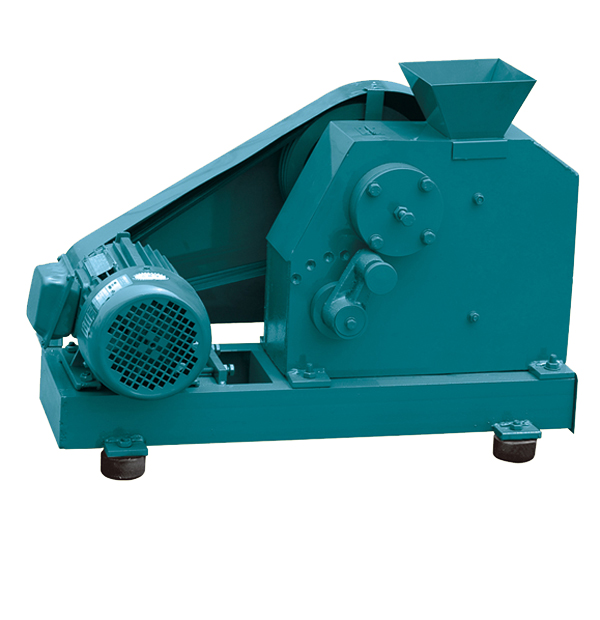

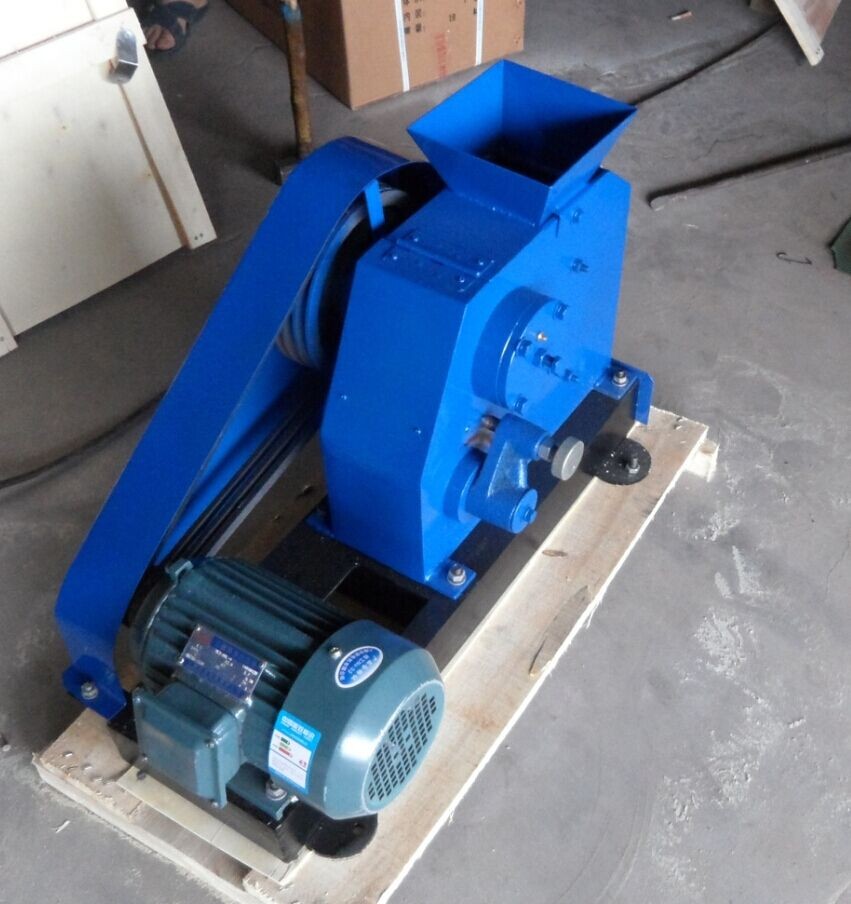

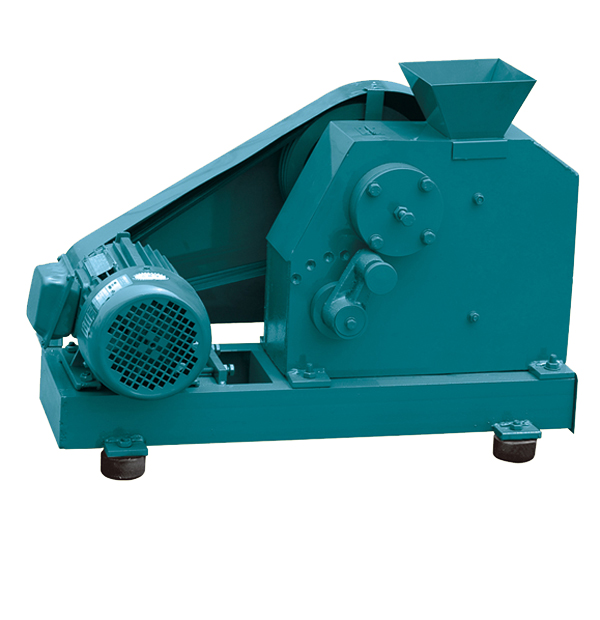

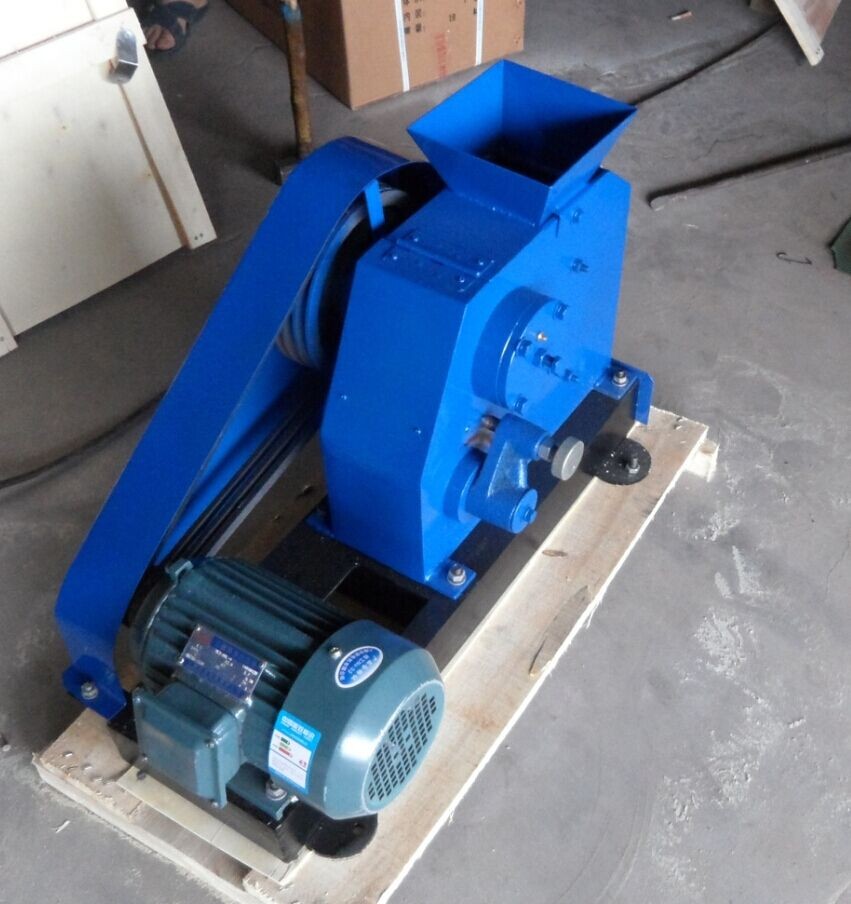

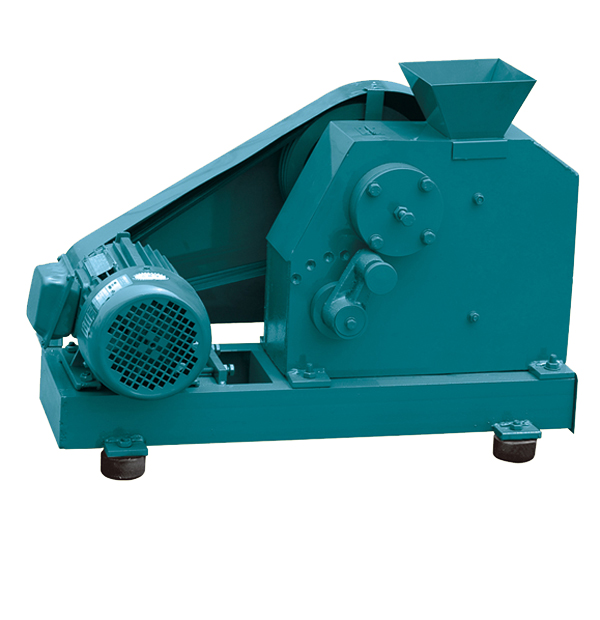

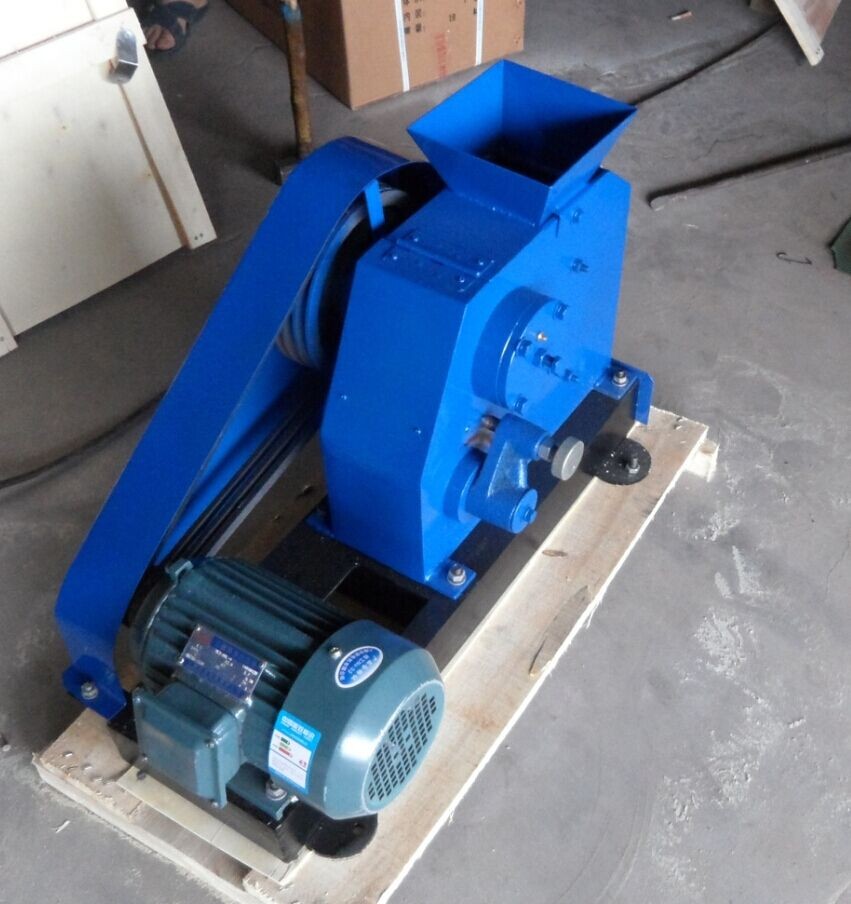

The Electric Motor drives the belt and the pulley through the eccentric shaft to move the movable jaw up and down. When the movable jaw rises, the angle between the elbow plate and the movable jaw increases, thus pushing the jaw plate toward the fixed jaw plate The angle between the toggle plate and the movable jaw becomes smaller when the movable jaw goes down, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring. With the continuous rotation of the motor, the movable jaw of the crusher is used for periodic crushing and discharging of materials, thus realizing mass production. 一、 Overview Jaw crusher is used in mining, metallurgy, geology, building materials, light industry, chemical industry and engaged in the inspection of the unit. The machine is made of weld steel, high manganese steel, cast iron. each unit are strictly commissioning, before leaving the factory after the full qualified, as a result of the quality of the unit itself, our plant is responsible for three guarantees.It is normal wear and tear of wearing parts, need to buy or additions can contact with us, our plant responsible for supplying transport agent.Our purpose is: quality first, the customer first. 二、 the structure of jaw crusher The machine consists of frame, movable jaw, eccentric shaft, jaw plates, brackets and other components. Motor through V-belt twirls off-axis, so that the movable jaw shall be carried out in accordance with the has adjusted well trajectory. material in the crushing chamber will be broken.The frame is formed by a plate welded.Frame,front chamber is fised with tune jaw plate. fitted with the protective cover on the right side surface, in order to ensure safety.Fixed, movable jaw is component of the casting, with the movable jaw in the front, by means of the eccentric shaft and the upper roller bearing is suspended on the frame.Lower installed on the dental plate. The eccentric shaft end is equipped with geneva wheel. On the right side is equipped with the handle to adjust the distance, easy to adjust the proper spacing.

| Model (Inlet size) | Voltage(V) | Power(kw) | Input size(mm) | Output size(mm) | Spindle speed(r/min) | capacity(kg/hour) | Overall dimensions (mm) D*W*H |

| 100*60mm | 380V/50HZ | 1.5 | ≤50 | 2~13 | 600 | 45~550 | 750*370*480 |

| 100*100mm | 380V/50HZ | 1.5 | ≤80 | 3~25 | 600 | 60~850 | 820*360*520 |

| 150*125mm | 380V/50HZ | 3 | ≤120 | 4~45 | 375 | 500~3000 | 960*400*650 |